Portable Appliance Testing (PAT)

Why PAT Test?

PAT testing was introduced to ensure that all electrical appliance are safely maintained and suitable for the environment in which they are used. This involves periodic planned inspection and testing of portable appliances to meet all required standards and regulations. The Electricity at Work Regulations states that it is a legal requirement that employers maintain their electrical systems at work to prevent any danger.

Health And Safety Legislation

The legislation of specific relevance to electrical maintenance is the Health and Safety at Work Act 1974, the Management of Health and Safety at Work Regulations 1999, the Electricity at Work Regulations 1989, the Workplace (Health, Safety and Welfare) Regulations 1992 and the Provision and Use of Work Equipment Regulations 1998.

The Health and Safety at Work Act 1974 puts the duty of care upon both the employer and the employee to ensure the safety of all persons using the work premises. This includes the self employed.

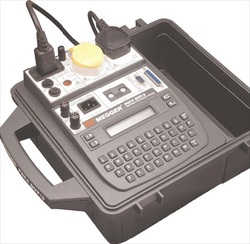

The IEE Code of Practice for In Service Inspection and Testing of Equipment sets out the standard to which each appliance is comprehensively tested. It is recommended that you use the latest computerised PAT testing equipment or hire a professional company which can offer you this service. All portable appliances will need testing such as IT equipment, kettles and microwaves. The inspection and testing should be carried out by a fully qualified PAT testing engineer.

What Types Of Appliances Need PAT Testing?

There are different classifications for electrical appliances and the tests that are required, below are some classification examples and the applied testing.

Each appliance will undergo a thorough visual inspection to check the correct fuse type is fitted and to ensure that there are no signs of damage to the flex, casing or plug.

Class 1. This equipment includes toasters, kettles, irons, microwaves, fridge freezers, heaters etc. These items require an earth

continuity test, insulation resistance test and a protective earth conductor current test.

Class 2. This equipment includes some stereo equipment, televisions, lamps, vacuum cleaners etc. These items require an insulation resistance test and touch current test.

Information technology equipment (IT) includes computers, telecommunications, monitors, printers etc. These items require an earth

continuity test and an insulation resistance test.

Extension leads and detachable cables such as an IEC lead are classed as a separate item and require an earth

continuity test, an insulation resistance test and a polarity test.

Hand held equipment includes appliance intended to be held in the hand during normal use, drills, hair dryers etc. Most of these appliances are class 2 but occasionally can be class 1

Microwave Leakage Test. In addition to the electrical test a microwave radiation leakage test is highly recommended, the doors are checked for corrosion, the seals are checked for signs of wear or damage. Finally a test meter is used to ensure that no dangerous microwave emissions are detected.

PAT testing was introduced to ensure that all electrical appliance are safely maintained and suitable for the environment in which they are used. This involves periodic planned inspection and testing of portable appliances to meet all required standards and regulations. The Electricity at Work Regulations states that it is a legal requirement that employers maintain their electrical systems at work to prevent any danger.

Health And Safety Legislation

The legislation of specific relevance to electrical maintenance is the Health and Safety at Work Act 1974, the Management of Health and Safety at Work Regulations 1999, the Electricity at Work Regulations 1989, the Workplace (Health, Safety and Welfare) Regulations 1992 and the Provision and Use of Work Equipment Regulations 1998.

The Health and Safety at Work Act 1974 puts the duty of care upon both the employer and the employee to ensure the safety of all persons using the work premises. This includes the self employed.

The IEE Code of Practice for In Service Inspection and Testing of Equipment sets out the standard to which each appliance is comprehensively tested. It is recommended that you use the latest computerised PAT testing equipment or hire a professional company which can offer you this service. All portable appliances will need testing such as IT equipment, kettles and microwaves. The inspection and testing should be carried out by a fully qualified PAT testing engineer.

What Types Of Appliances Need PAT Testing?

There are different classifications for electrical appliances and the tests that are required, below are some classification examples and the applied testing.

Each appliance will undergo a thorough visual inspection to check the correct fuse type is fitted and to ensure that there are no signs of damage to the flex, casing or plug.

Class 1. This equipment includes toasters, kettles, irons, microwaves, fridge freezers, heaters etc. These items require an earth

continuity test, insulation resistance test and a protective earth conductor current test.

Class 2. This equipment includes some stereo equipment, televisions, lamps, vacuum cleaners etc. These items require an insulation resistance test and touch current test.

Information technology equipment (IT) includes computers, telecommunications, monitors, printers etc. These items require an earth

continuity test and an insulation resistance test.

Extension leads and detachable cables such as an IEC lead are classed as a separate item and require an earth

continuity test, an insulation resistance test and a polarity test.

Hand held equipment includes appliance intended to be held in the hand during normal use, drills, hair dryers etc. Most of these appliances are class 2 but occasionally can be class 1

Microwave Leakage Test. In addition to the electrical test a microwave radiation leakage test is highly recommended, the doors are checked for corrosion, the seals are checked for signs of wear or damage. Finally a test meter is used to ensure that no dangerous microwave emissions are detected.